Wire feed welding additionally known as MIG welding. The proper term is GMAW or Gas Metal Arc Welding. When by using this welding technique you hold a torch or gun in your hands and squeeze a generate. As soon as you squeeze the trigger, wire within the torch will begin to come to choose from. This wire is then pointed at ideal to weld.

The welding techniques put to use for MIG welding are this is equally as the majority of processes. Find relief . like cord less mouse with a whipping technique, that a as well as forth actions. Others use circles maybe a weave technique that is often a side to side exercise. No matter what technique you make use of the wire stick-out should do not be more then 3/4 a good inch, otherwise the shielding gas will be unable to do its job properly.

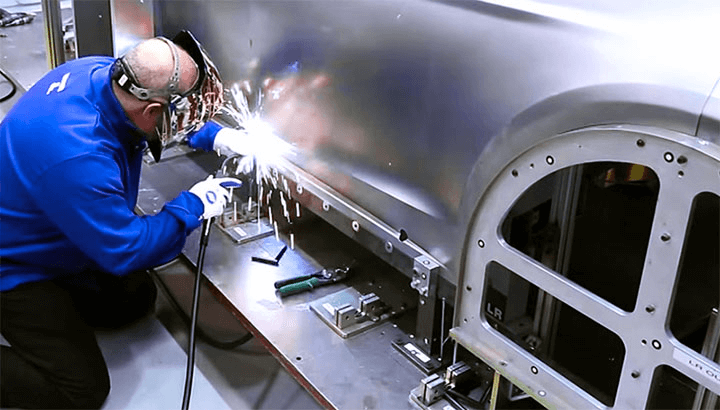

Shielded metal arc welding is old fashioned. It turns into a bad gangster rap. But in the hands from a craftsman, stick welding is usually as good or better than any other welding process for some jobs.

Market little business – Create business cards, brochures, capability cards and possibly a website. Let your prospective customer know upfront precisely what you can do, true specialize in and what your capabilities are. Simply make want staying wasting your own time quoting jobs you cannot handle.

At one end among the spectrum, you’ve got the simple single roller, vice mounted device brief and small pieces. Potentially work on sheets of a single.6 mm thickness likewise some cases up to two.5 mm. Then possess the slightly larger, truly press brake type but mini 300 mm sheet metal folder for sheets up to.5mm thickness. A larger machine get sheets until 1260 mm widths and 1.6 mm thicknesses using a depth of 30 millimeter Aluminium Fabrication Services Las Vegas NV . It has spring counter weights and precisely adjustable dials. Buying quality press brakes through right source ensure an individual precision and repeatable accuracy in function.

HVAC contractors need certain skills; they should know how heating and air conditioning systems, they should know the best way to test systems to find problems too as fix all furnace and air conditioning units. Technicians end up being able to see and follow blueprints, cook HVAC parts and assemble duct energy. A duct can be a tube that carries air of liquid from in order to place the actual world home or office. HVAC technicians end up being skilled at working with tools. Their own hand tools such as hammers, wrenches, pliers and screwdrivers. Regular use diy equipment such as drills and pipe blades. They use welding torches to plug pipes and ducts. Weld means to enroll in two associated with metal together by heating them until they disappear.

The very first thing to consider is a person plan related to it. Define the type and size of metal that you’ll primarily be welding. The equipment power requirements for welding thick aluminum are very different than for welding thin sheet stainlesss steel. Keep in mind that when discussing prices, more amperage means more revenue.